Customised services

In the modern world of manufacturing, flexible, customer-orientated services play a crucial role for us in order to meet the growing demands for precision, efficiency and individuality. Solutions such as the creation of 3D models, the cutting of profiles to specific lengths or the provision of customised coil sizes create essential added value for our customers and their production processes.

Speeds up further processing

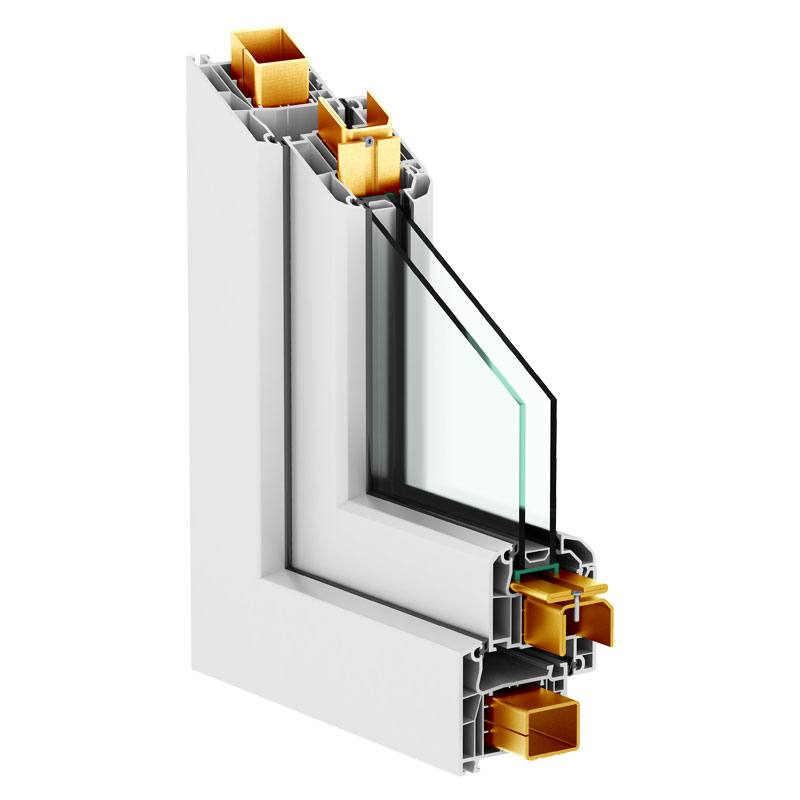

Cutting profiles to fixed lengths is an essential step in many manufacturing processes. Precision and repeat accuracy are of key importance here, especially for applications in the construction or mechanical engineering industry.

- Cost efficiency: Precise cutting minimises material waste, which not only saves costs but also contributes to sustainability.

- Time saving: Pre-cut lengths reduce the customer's processing effort and speed up further processing.

- Customised adaptations: We can take specific dimensions and tolerances into account in order to optimally cater to our customers' needs.

Modern machines enable us to cut with maximum precision, even with complex profile geometries or challenging materials such as aluminium or stainless steel.

From idea to tangible reality

3D models form the basis for innovative product development. Using advanced CAD programmes and 3D printing technologies, we can create prototypes that quickly and precisely transform design concepts into physical objects.

The advantages of such prototypes are obvious:

- Faster product development: design errors or optimisation potential can be identified and rectified at an early stage before expensive tools or production facilities are created.

- Individual adaptability: Thanks to the flexibility of digital modelling, prototypes can be specifically adapted to customer requirements.

- Realistic testing: Physical models enable functional tests and visual checks that digital renderings alone cannot provide.

With this service, we make the transition from the concept phase to series production much easier and create the basis for successful market-ready products.

Flexibility for every requirement

In many industries, standardised material bundles are not always the optimal solution. Customised bundle sizes offer an attractive alternative here, as they can be adapted precisely to the material requirements and process requirements.

- Logistical advantages: Customised bundle sizes make transport and storage easier, especially in companies with limited space.

- Production optimisation: Precisely measured material quantities simplify handling in production and avoid unnecessary changeover times.

- Conservation of resources: Customers order exactly what they need - no overproduction, no unnecessary leftovers.

This service emphasises the importance of individuality at a time when production lines are becoming increasingly automated and customised.