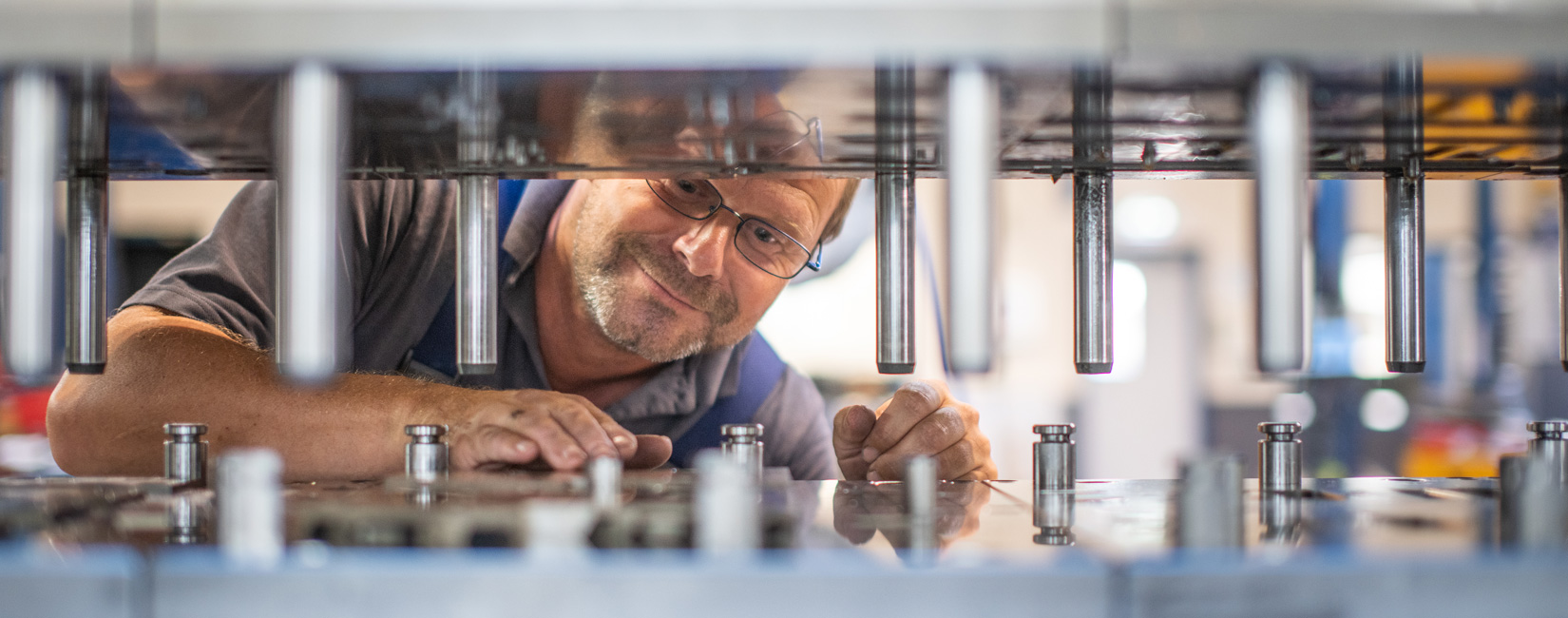

Punching

Thanks to our 26 state-of-the-art punching presses, which are equipped with a pressing force of 12 to 800 tonnes, we have the technical diversity to meet a wide range of requirements. Whether it is the production of small, precise stamped parts or large, complex components, we offer solutions that are both economical and of high quality. Each of our presses is designed for maximum efficiency and precision, which enables us to realise series production just as reliably as individual orders.

But we go beyond just stamping: to ensure that our products are optimally prepared for their area of application, we offer a wide range of processing options. These include galvanising to prevent surface corrosion, powder coating for an aesthetic and durable finish, and chrome plating, which provides a high-quality look as well as protection against wear and chemical influences. In addition, we offer spot welding to create robust connections and thread cutting, which is particularly important for assembly purposes.

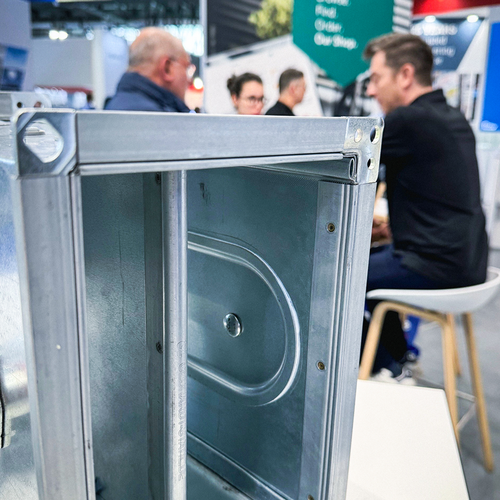

Bending

We use state-of-the-art machines with an impressive press force of up to 200 tonnes for precise, high-quality bending work. These high-performance systems enable us to process a wide range of materials and sheet thicknesses with the highest precision. Whether it's delicate parts for prototype construction or large-format components for series production, our bending technology is versatile and designed for maximum precision.

A particular focus is on the combination of modern technology and automation. With the help of robots, we can fully automate bending processes, which not only increases efficiency but also the reproducibility of the results. The robots take over the precise positioning and handling of the workpieces, which offers enormous advantages, especially for complex or large-volume series production. At the same time, they guarantee consistent quality, regardless of the production quantity.

For special requirements or individual pieces, we rely on manual bending using the single-stroke method. This method allows for particularly flexible and customised processing, which is ideal for smaller series or sophisticated custom-made products.

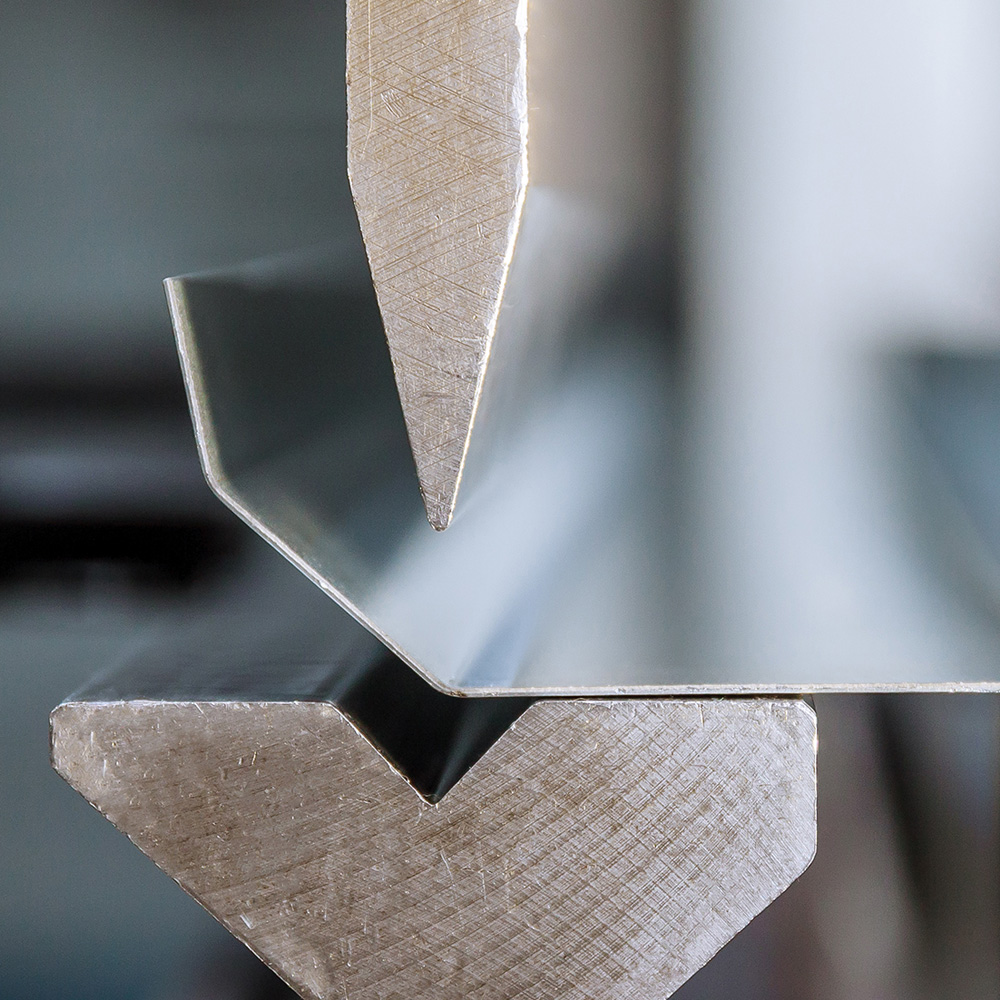

Laser cutting

Our high-performance laser cutting systems set standards in the precise and flexible processing of materials. With an impressive cutting performance, we can effortlessly process sheet metal and other materials up to 15 mm thick. This process combines precision, efficiency and versatility, allowing us to cover a wide range of our customers' requirements.

Laser cutting is particularly suitable for the production of prototypes where maximum precision and short production times are required. It enables us to realise innovative product ideas in the shortest possible time and create the basis for efficient further development. It is also ideal for the production of individual parts where customised dimensions and special requirements play an important role. Our customers in pre-series production also benefit from the flexibility of this process, which allows smaller quantities to be realised with minimal effort - perfect for testing designs and functions prior to large-scale production.

In addition to the exceptional accuracy achieved by the high-precision control of the laser beams, the process is characterised by outstanding cutting quality. The edges produced are clean, smooth and often ready for immediate use without post-processing. This not only reduces production time, but also helps to reduce costs and increase efficiency.